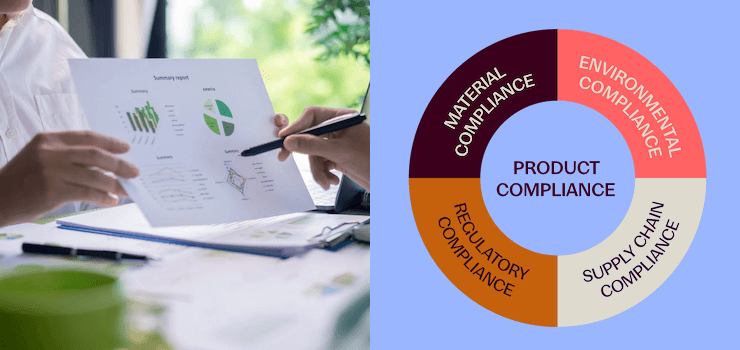

In the dynamic world of industrial production, compliance and regulatory conformity are crucial. On the one hand, they enable access to different markets; on the other hand, the number of product and material regulations increases exponentially over time and represents a major challenge, especially for companies with complex products and supply chains.

With iPoint Compliance, not only a powerful but also a highly efficient tool is available, which helps to manage the effort of compliance activities with well thought-out digitalization and a high degree of smart automation. iPoint Compliance illuminates the supply chain down to the material level and reports against numerous regulations that must be complied with.

Skilful implementation of these regulations in software content is the heart and soul of automated and therefore efficient compliance checks: They enable industries to bring products to market quickly, to reliably plan new products and ultimately to optimize them in line with the market.

CSI – Compliance and Substance Inspector: On the Trail of Data.

iPoint Compliance reflects the specifications, rules and laws in so-called Compliance and Substance Rulegroups (CS Rulegroups). Behind this is a team of experts who have only one job: To maintain, update existing and create new rule groups.

It goes without saying that sets of rules are not set in stone. Currently, for example, there are more and more environmental issues that are increasingly coming into focus with different aspects and that need to be closely monitored. Be it recurring adjustments to existing regulations or the emergence of new ones. Discussions about laws and regulations at national and supranational level speak for themselves. Software must react to changes all the more reliably:

Extensions, changes, deletions - promptly, comprehensibly and resiliently. Updates are affected by legal requirements (e.g. EU-REACH, EU-ELV...), industry-specific regulations (e.g. GADSL in the automotive industry) but also company-specific restrictions (e.g. large automotive OEMs). Suppliers are obliged to adhere to these restrictions in order not to lose market share. They are subject to constant controls.

In addition to generally applicable regulations, (almost) every industry has its own specifications. Together with the requirements of individual companies or entire industry associations, this results in a whole catalogue of rules and the accompanying explanatory works. Understanding what they mean, how they are used, how they need to be woven into the daily process and the work of the compliance engineer - that is the job of our experts. They ensure that the groups are sorted by industry, bundled and made available according to individual wishes. But this also means that care must be taken for each individual to know what has changed, what will change and in which direction the market, society and ultimately also legislation is moving. Reliable predictions and assessments from the associations and consortia are decisive here and are professionally followed and analysed by our experts. And not only as a silent domain observer but also as an active participant in various research projects and committees.

What will change in 2024: What can I see on the horizon, how can you best prepare for new challenges? The discussions about PFAS Compliance and Regulations and the like are making experts sit up and take notice and look forward with anticipation to what is likely to come.

Watch the recording of our webinar "Product Compliance Update 2023 - Review & Outlook": In the video we will show you outlooks and important key topics. EU-REACH - status quo? - 3 years of SCIP reporting - news on TSCA and California Proposition 65 and last but not least PFAS ahead: what to do first?

.png)