Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector

There is consensus that digital technologies (DTs) can offer a range of potential benefits for implementing a circular economy in manufacturing companies. However, to understand these benefits, we need to learn much more about how different DTs are being used in different industries. A recent study by the Christian Doppler Laboratory for Sustainable Product Management, which is co-funded by iPoint Systems, aimed to fill this gap by analyzing data from a structured survey of 132 sustainability managers and CEOs of Austrian manufacturing companies. The survey asked about the implementation of four key DTs (Internet of Things (IoT), big data analytics, artificial intelligence, and blockchain technology) and 31 specific applications of those technologies across eight different industries.

Digital technologies are still underutilized

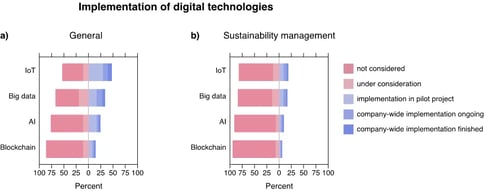

As can be seen in Figure 1. IoT technology is the most widely implemented DT, followed by big data analytics, artificial intelligence, and blockchain technology. However, their use in sustainability management is still very limited and is mainly in pilot phases.

Figure 1: Use of digital technologies a) in general and b) for sustainability management (n = 132). Abbreviations: IoT, internet of things; AI, artificial intelligence.

The most common use of IoT technology is for collecting data from production processes, while artificial intelligence is most frequently used for predictive maintenance, big data analytics for demand forecasting, and blockchain technology for tracking product origins (see Figure 2).

.webp?width=487&height=301&name=image-png-4%20(1).webp)

Figure 2: Degree of implementation of a) internet of things technology, b) big data analytics, c) artificial intelligence, d) blockchain technology (n = 132). SC = supply chain, EOL = end of life, Mgmt. = management.

Industry affiliation and company size matter

The study further showed that the implementation level of DTs varies significantly depending on a company’s industry affiliation. Forerunner companies with the company-wide implementation of several specific applications come from the electronics, machinery and metals, chemical and construction industries (see Figure 3). In contrast, companies from the food industry in the sample did not report much in the way of using DTs in practice. In line with previous research that showed that most examples come from large international corporations (Rusch et al., 2022), the study also found that large companies are significantly more likely to adopt DTs than small companies in general, and, tendentially also in a sustainability management context. Finally, a strong positive correlation was also found between the implementation of DTs in general and their use in sustainability management, indicating potential synergies and spillover effects.

.webp?width=487&height=324&name=image-png-3%20(1).webp)

Figure 3: Percentage of companies implementing a specific digital technology in general and for sustainability management (_sus) per industry. The percentages summarize the following response options: implementation in a pilot project, company-wide implementation ongoing and company-wide implementation finished. The distribution is normalized to 1 (i.e. 100 %) by industry (i.e., by row) (n = 132). IoT = internet of things; AI = artificial intelligence.

What are the managerial implications?

While DTs have the potential to support the transition to a more sustainable and circular economy, it was confirmed that their use in this context is still in the early stages and mainly limited to pilot projects. This suggests that there is still much to learn about how best to leverage the benefits of DTs in this context, and further research is needed to identify scalable best practices, optimal enabling conditions, and environmental and social outcomes.

In the meantime, managers can use the findings of this study to inform the development of context-specific and purpose-driven strategies that selectively leverage the benefits of different DTs for sustainability management. By understanding the specific DTs and applications that are most commonly used in different industries and for different sustainability management goals, managers can make more informed decisions about which technologies to invest in and how to use them most effectively.

In addition, the strong positive correlation between the implementation of digital technologies in general and their use in sustainability management highlights the potential for synergies and spillover effects. This suggests that companies that are already investing in DTs for other purposes may be well-positioned to leverage those technologies for sustainability management as well. Finally, companies also need to prevent potential lock-ins and economic and environmental rebound effects in their digitalization efforts. This entails more explicit recognition of the many purposes for which DTs may be applied.

Open access to the full study

This study was published in “Sustainable Product and Consumption” and the full paper „Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector “ by Josef-Peter Schöggl, PhD., Magdalena Rusch, MSc., Lukas Stumpf, MSc., and Prof. Dr. Rupert J. Baumgartner can be read here: https://doi.org/10.1016/j.spc.2022.11.012

References

Rusch, M., Schöggl, J.-P., & Baumgartner, R. J. (2021). Application of digital technologies for sustainable product management in a circular economy: A review. Business Strategy and the Environment. https://doi.org/10.1002/bse.3099