Properly utilized data is a valuable resource. In our increasingly digital world, most efficiency gains, reductions in cost, increases in speed, and quality of decision-making come from the ability to put data to work.

At iPoint, we treat data as the raw material required for good decision making. It is the starting point for synchronizing, optimizing, and automating business processes.

The era of Big Data and Cloud computing has reduced the costs and complexities of data storage and computing power. In fact, ICT infrastructure has never been more affordable and able to support holistic and integrated software solutions required to:

- Shorten the product development cycle to achieve faster go-to-market,

- Smoothly scale up new production processes and technologies,

- Improve supply chain traceability and data transparency

- Measure, track, and improve social and environmental performance,

- Leverage data as a strategic asset to gain competitive advantage,

- Reduce costs and risks by automating rules, responsibilities, and workflows, and

- Eliminate high-risk and non-compliant materials as early as possible.

These strategic objectives point to the need to better integrate and utilize data for business outcomes. iPoint enables companies to achieve this without having to worry about developing new ICT infrastructure and complex software. With iPoint’s solutions, companies can collect and analyze all necessary data to assess, report, and make decisions about the environmental, social, and economic performance of their products, supply chains, and production.

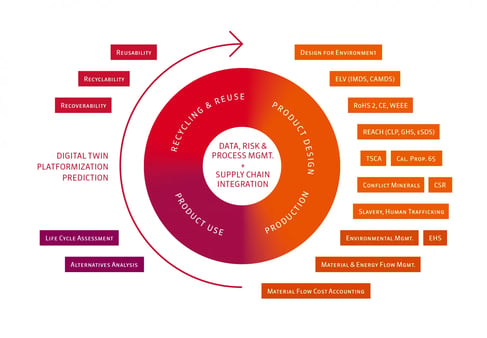

More importantly, iPoint provides integrated solutions to address the entire product lifecycle.

Compliance and sustainability are a part of the same circle

Since iPoint’s foundation in 2001, our focus on the entire product lifecycle hasn’t changed. As a result, our solutions have evolved to support everything from product and material compliance requirements to supporting sustainability and circular economy goals and targets. We have been proponents of the digital circular economy since 2014 – which is reflected in the iPoint Circle of solutions.

From Compliance to Sustainability: Digital Circular Economy

From Compliance to Sustainability: Digital Circular Economy

New and emerging regulations and directives targeting carbon emissions, recyclability, and extended producer responsibility are completely erasing this line between compliance and sustainability. For years, we have anticipated this, and worked to build holistic solutions.

This article is the sixth in our series of nine articles dedicated to the topic “From Compliance to Sustainability – Managing Material Lifecycle in the Circular Economy Era”. It is addressed to senior decision makers, managers, compliance officers, engineers, and any corporate citizen interested in the most important steps of your journey from compliance to sustainability. Starting with material compliance, we will explore the entire material life cycle and the connections between corporate sustainability goals, circular economy, and digital technology. Thereby, we will lay the focus on business processes, IT solutions, and the utilization of data as the three key elements which – in combination with sustainability and the circular economy – create greater value for companies and their value chains.

This article is the sixth in our series of nine articles dedicated to the topic “From Compliance to Sustainability – Managing Material Lifecycle in the Circular Economy Era”. It is addressed to senior decision makers, managers, compliance officers, engineers, and any corporate citizen interested in the most important steps of your journey from compliance to sustainability. Starting with material compliance, we will explore the entire material life cycle and the connections between corporate sustainability goals, circular economy, and digital technology. Thereby, we will lay the focus on business processes, IT solutions, and the utilization of data as the three key elements which – in combination with sustainability and the circular economy – create greater value for companies and their value chains.

Stay tuned for our next article in this series, which will focus on iPoint’s role and why we see compliance and sustainability as part of the same circle.

About the authors

Maroye Marinkovic is the Product Innovation Manager at iPoint, where he brings in his skills as a solution designer, digital strategist, and a communicator with a passion for improving sustainability, efficiency, and compliance across value chains. Based in Melbourne, Australia, he has more than 10 years of experience in conceptualizing, designing, and implementing enterprise compliance, sustainability, and risk management software solutions. Maroye’s specializations include chemicals management, platform design, blockchain solution design, circular economy, and business strategy.

Dr. Bing Xu joined iPoint in Ann Arbor, Michigan, at the North America main office in 2019 as Director of Business Innovation. In this role, he supports iPoint’s customers in different industries with their material compliance programs as well as their sustainability, circular economy, and digital twin projects, to integrate material compliance programs into their core product development processes and reduce non-compliance risks and improve engineering efficiency.

Before joining iPoint, Dr. Xu was Ford Motor Company’s Global Materials Compliance Program Manager. Spearheading Ford’s Global Materials Management program in early 1997, he was one of the original OEM members who developed and launched the International Data Management System (IMDS) for the automotive industry in 2000. He was Ford’s global attribute leader for material/substance compliance and material life cycle management, and a member of Ford’s Sustainability Council, managing both internal compliance and external suppliers’ compliance. He also led Ford’s cross-functional teams and developed various material compliance-related processes and IT tools for Ford since 1997. Furthermore, Dr. Xu was the owner of Ford’s Restrictive Substances Management Standard (RSMS) and the owner of the Ford’s internal material/substance compliance processes/tools.

He has served as chair and co-chair in several committees of leading industry organizations and work groups, such as the US Automotive Industry Action Group (AIAG)’s Chemical Management Advisory Group, the United States Council for Automotive Research (USCAR)’s Substances of Concern Group, the Global Automotive Declarable Substance List (GADSL)’s Steering Group; and he has supported projects of the US Environmental Protection Agency (EPA) on Alternative Assessments, and TSCA industrial data collection and evaluations.

A recognized and highly respected expert of the automotive industry, he has been invited to speak at many conferences and forums hosted by different industries and governmental agencies, e.g., Electronics, Building Materials, Heavy Machinery, Chemicals, Apparel, Home Appliances, California Safer Consumer Products and Alternative Assessment conferences/workshops, and SAE US Government Industry Meeting.