How will we make Hamburg’s industry more efficient and sustainable? To answer this question, the “MFCA-Hamburg” project was launched as a cooperation between ifu Hamburg, the Hamburg Environmental Authority and the University of Hamburg. The project will support 10 local industrial companies to develop an analysis of the material flow costs of their production processes and to identify individual potentials for a more efficient and sustainable production.

At the Resource Efficiency Meeting 2018, an event organised by ifu Hamburg, the project was presented for the first time by Björn Dietrich (Hamburg Environmental Authority) and Jan Hedemann (ifu Hamburg GmbH). More than 80 representatives from industry, consulting and research came together at the meeting to exchange ideas on topics related to resource efficiency and to present practical solutions.

As head of the energy department, Björn Dietrich is primarily concerned with promoting a more sustainable energy policy and economy in Hamburg, among others by increasing resource and material efficiency in companies in Hamburg. This is where Jan Hedemann, Managing Director of ifu Hamburg, comes into play. As experts for material and energy efficiency, he and his team support companies on their way to sustainable production with the help of software and consulting.

What is MFCA?

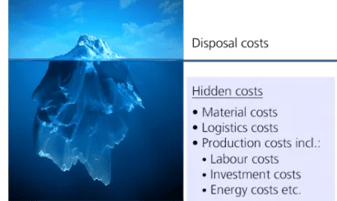

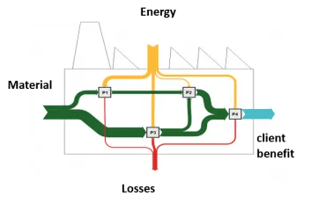

“The aim of material flow cost accounting (MFCA) is to add a new cost perspective, which illustrates the complete costs of waste” says Jan Hedemann. Conventional cost accounting addresses costs linked to waste in most cases only as disposal costs. However, this perspective usually only captures the tip of the waste cost iceberg. The MFCA approach in contrast aims to also unfold hidden costs that incur with waste production, such as costs for raw material, transport and production. Identifying these invisible waste-related costs via MFCA is an important step towards increasing material efficiency and improving cost efficiency.

“The aim of material flow cost accounting (MFCA) is to add a new cost perspective, which illustrates the complete costs of waste” says Jan Hedemann. Conventional cost accounting addresses costs linked to waste in most cases only as disposal costs. However, this perspective usually only captures the tip of the waste cost iceberg. The MFCA approach in contrast aims to also unfold hidden costs that incur with waste production, such as costs for raw material, transport and production. Identifying these invisible waste-related costs via MFCA is an important step towards increasing material efficiency and improving cost efficiency.

What’s the plan of MFCA Hamburg?

In this project 10 companies from Hamburg will be supported in carrying out an individual material flow cost calculation for their production. This application of MFCA will ultimately help decision makers within the companies at recognizing potentials for optimizing material efficiency. In addition, in the MFCA Hamburg project, the participating companies will identify the climate impact related to wastage in their systems. Thus, improvements will be assessed according to potential cost savings as well as to potential reductions in climate impact.

With their expertise in MFCA and with the aid of the software tool Umberto Efficiency+, the ifu-Team will support the companies in this task. Moreover, the University of Hamburg will accompany this project, creating a tighter link between science and industry. For this purpose, a new seminar series on “Applied Environmental Management” has been started. Master students participating in these seminars will support the companies by conducting an MFCA analysis as part of their final thesis.

Dr. Björn Dietrich: “With this project, we aim to create win-win situations for the participating companies and demonstrate that resource efficiency does not only mean a relief for the environment, but that it also enables companies to position themselves better for the future”. By telling success stories of the participating companies, the MFCA Hamburg project will create flagships for more resource efficiency in Hamburg’s industry!

Presentations and videos of the Resource Efficiency Meeting are available at https://www.ifu.com/events/ressourceneffizienz-treff/ (sorry, in German only).