ifu Hamburg GmbH, member of iPoint Group, HTW Berlin and UKOM jointly supported SMEs in using the MFCA methodology to achieve higher material efficiency. Our consultants provided support in the analysis process and practical consulting within the SMEs. The project was funded by the “Deutsche Bundesstiftung Umwelt” (DBU) as part of the research project “MFCA mobil”.

This case study focuses on how iPoint helped Junker Filter GmbH to reduce the use of resources in their filter systems by using the MFCA method. Junker Filter GmbH manufactures filter components from technical textiles.

The case ZERO® Design

One of the company’s core products is the ZERO® Design product series, which is produced to meet ever-increasing emission limits. Such filters are primarily used in the food, beverage and pharmaceutical industries. These models consist of seamless filter bags with absolute fitting accuracy, which are encased in plastic at the ends. The plastic is cast by hand using a limited number of molds. At the start of the project, 32 minutes are required for the production of 4 filters each, including curing.

Automation of processes to increase production efficiency

The basic aim of the project was to carry out a material flow cost analysis (MFCA) of the ZERO Design product line. This is intended to show whether, where and how resources can be saved in the production process. It is expected that the systematic recording of all key figures of the production technology will increase the interdepartmental system understanding within the company. At the same time, it should be shown where the greatest value-added losses occur during production. Within the framework of MFCA, the modeling of different scenarios is to examine how production efficiency can be significantly increased by automating individual work steps.

Develop a model for the manufacturing processes

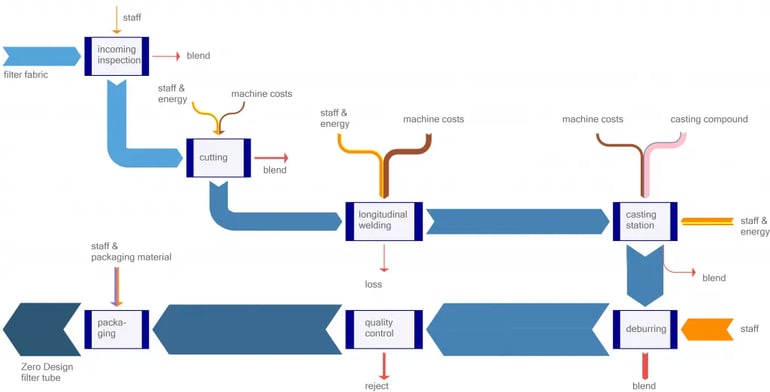

First, all material flows of the ZERO Design product line were recorded. For this purpose, all parameters of costs, working times and losses in the running operation were determined step by step: From the receipt and sampling of the individual textile fabrics as well as the subsequent seamless production, to the receipt of the plastics for the molding as well as the joining and gating of the components, to the quality inspection and delivery of the filters. A model was developed and parameterized from the actual data determined for the manufacturing processes. This enabled scenario analyses to be carried out for changeovers in the various production processes. In detail, the following were of interest:

- A varied filter bag length

- Manual versus automated operation of the casting station

- Variation of casting molds

- Variation of material quantities

All scenarios calculated for the casting station took burr formation on the cast filter heads into account. Burr formation influences the material requirement as well as the time for manual reworking. At the same time, it is a safety factor for high quality.

“As a highly specialized technology company, it is of enormous importance for us to continuously expand our know-how. In doing so, investments in the expansion of our production processes must be as sustainable as they are profitable. For the analysis and strategic planning of our manufacturing processes, the MFCA methodology convinced us. Moreover, the associated coaching showed us how we can optimally use our environmental key figures as a unique selling proposition (USP) in product tenders.”

Julian Nuss, commercial manager

Result: For total transparency of the cost structure

The results of the material flow cost analysis led to complete transparency of the cost structure of their filter hose production for Junker Filter GmbH. On the material side, significant losses in plastic casting and the subsequent rinsing processes could be identified as hotspots. In addition, a high time expenditure in the manual casting process was demonstrated. The optimization potentials broken down in the scenario analyses led to the following recommendations:

- optimized geometry of plastic castings reduces the need for raw material with a manageable investment in new molds.

- reduction of total production costs by 20%: Increased number of casts per cycle (8 instead of 4) reduces the number of rinsing operations while providing higher efficiency per worker.

- savings of 40% in total product costs: an even higher increase in productivity could be achieved by automating the casting station on a rotary basis. After a significant investment in the company’s infrastructure, 41 filter bags could be produced in 40 minutes in the rotary run.

The detailed data collection in the context of material flow cost analysis provides Junker Filter GmbH with valuable information for anchoring the material flow management methodology in the company across all processes. In addition to process optimization, the data can be used for CO2 evaluations in the future.

If you want to read another case study on MFCA, then click here.

About the Company

“Products of tomorrow to increase productivity and protect our environment” is the corporate motto of Junker Filter GmbH. Since 1956, the Sinsheim-based company has been developing technologies and products for the use of technical textiles in the latest dedusting systems and in solid-liquid separation. With innovations in filtration, Junker Filter internationally offers a cross-industry range of products and services from individual customization to series production.