Materials and substances are the fundamental building blocks required to produce bigger components, then large assemblies, and finally complete physical products such as smart phones, medical devices, pickup trucks, electric SUVs, tractors, and airplanes. This is true whether you’re a small mom-and-pop shop or a major Fortune Global 500 corporation.

Material and substance management is a key area for any company that builds physical products.

Let’s examine the world of materials. In general, there are three types of materials:

- production materials – used to make engines in airplanes/vehicles, TV screens, medical equipment,

- non-production materials – used to run production, but not end up in production parts, e.g., conveyor belts, toilet papers, inks, packaging boxes to ship physical parts –, and

- post-production materials – including service materials and chemicals.

Each type of material includes two major categories: dimensional materials – i.e. articles with shape, hard parts, e.g., medical needles, rubber balls, and steels – and non-dimensional materials – i.e. wet chemicals, mixtures, and fluids.

Materials and substances are often managed in different ways.

Production, non-production, and post-production materials and substances are often managed in different ways, resulting in multiple processes across multiple departments and business units. In many cases, these processes have evolved separately, at different times, with different objectives in mind, and often using different IT tools and databases. Material and substance management is quite a complex task, and considering its direct impact on company operations and the bottom line, it deserves attention.

Complying with various governmental material and substance-related regulations is a must for every company which produces physical products. With the increasing industrialization, many new regulations started to emerge, in particular at the end of the last century. For example, the European End of Life Vehicles Directive (ELV), developed in the late 1990s, regulates the end of life treatment of automotive products, including dimensional hard parts such as bumpers as well as non-dimensional materials such as oils and lubricants. Occupational safety and health regulatory requirements such as the Occupational Safety and Health Act (OSHA) have existed for quite a long time. OSHA regulates non-dimensional chemicals and mixtures that plant workers process and handle with the purpose to ensure that the health, safety, and environmental impacts are monitored and controlled. However, most finished articles are exempted from OSHA requirements, except for substances that may get released during the manufacturing process.

Regulations change and new ones emerge.

More and more regulations and directives are enacted to regulate both dimensional and non-dimensional materials and substances covering production, non-production, and post-production uses. The EU regulation REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), which came into force in 2007, has influenced other countries and jurisdictions to implement similar regulations.

Thereby, transparency and traceability are becoming key requirements. Consumers, investors, NGOs, and government agencies are demanding to know what’s inside the products companies produce and place on the market. “No data, no market”, the slogan of EU REACH, places responsibility on the industry to manage the risks from chemicals and to provide safety information on the substances. California Prop(osition) 65, officially known as the “Safe Drinking Water and Toxic Enforcement Act”, is another example of these “right-to-know” types of laws. Like with EU REACH, consumers have a right to request from companies that they disclose chemical compositions of their products. Companies are obligated to provide the data to consumers within a limited timeframe (e.g., 45 days under EU REACH). NGOs, on the other hand, have also been pushing the envelope to include more potentially hazardous and high-risk substances in future restriction lists.

More sophisticated processes and better tools needed.

When we add up all these complexities, risks, and challenges, the need for more sophisticated processes and better tools becomes obvious.

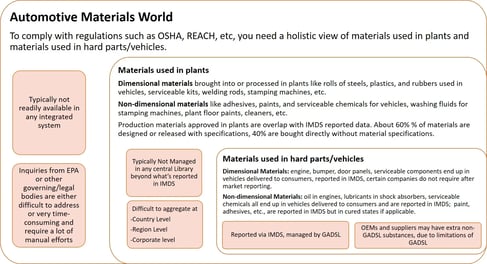

Below is a high-level diagram of how a typical “material world” looks like in the automotive industry. It illustrates how different materials (production, non-production, and post-production) are managed utilizing different processes and tools. Details will be explained in later posts.

*GADSL is the Global Automotive Declarable Substance List created in 2005 to manage substances of concern in the automotive industry,

*IMDS is the International Material Data System, a central database launched in 2000 for collecting all part, material, and substance data for automotive OEMs (Original Equipment Manufacturers)/suppliers.

This article is the first in our new series of nine articles dedicated to the topic “From Compliance to Sustainability – Managing Material Lifecycle in the Circular Economy Era”. It is addressed to senior decision makers, managers, compliance officers, engineers, and any corporate citizen interested in the most important steps of your journey from compliance to sustainability. Starting with material compliance, we will explore the entire material life cycle and the connections between corporate sustainability goals, circular economy, and digital technology. Thereby, we will lay the focus on business processes, IT solutions, and the utilization of data as the three key elements which – in combination with sustainability and the circular economy – create greater value for companies and their value chains.

The next article in this series, focus on the current state of material compliance management.

About the authors

Maroye Marinkovic is the Product Innovation Manager at iPoint, where he brings in his skills as a solution designer, digital strategist, and a communicator with a passion for improving sustainability, efficiency, and compliance across value chains. Based in Melbourne, Australia, he has more than 10 years of experience in conceptualizing, designing, and implementing enterprise compliance, sustainability, and risk management software solutions. Maroye’s specializations include chemicals management, platform design, blockchain solution design, circular economy, and business strategy.

Dr. Bing Xu joined iPoint in Ann Arbor, Michigan, at the North America main office in 2019 as Director of Business Innovation. In this role, he supports iPoint’s customers in different industries with their material compliance programs as well as their sustainability, circular economy, and digital twin projects, to integrate material compliance programs into their core product development processes and reduce non-compliance risks and improve engineering efficiency.

Before joining iPoint, Dr. Xu was Ford Motor Company’s Global Materials Compliance Program Manager. Spearheading Ford’s Global Materials Management program in early 1997, he was one of the original OEM members who developed and launched the International Data Management System (IMDS) for the automotive industry in 2000. He was Ford’s global attribute leader for material/substance compliance and material life cycle management, and a member of Ford’s Sustainability Council, managing both internal compliance and external suppliers’ compliance. He also led Ford’s cross-functional teams and developed various material compliance-related processes and IT tools for Ford since 1997. Furthermore, Dr. Xu was the owner of Ford’s Restrictive Substances Management Standard (RSMS) and the owner of the Ford’s internal material/substance compliance processes/tools.

He has served as chair and co-chair in several committees of leading industry organizations and work groups, such as the US Automotive Industry Action Group (AIAG)’s Chemical Management Advisory Group, the United States Council for Automotive Research (USCAR)’s Substances of Concern Group, the Global Automotive Declarable Substance List (GADSL)’s Steering Group; and he has supported projects of the US Environmental Protection Agency (EPA) on Alternative Assessments, and TSCA industrial data collection and evaluations.

A recognized and highly respected expert of the automotive industry, he has been invited to speak at many conferences and forums hosted by different industries and governmental agencies, e.g., Electronics, Building Materials, Heavy Machinery, Chemicals, Apparel, Home Appliances, California Safer Consumer Products and Alternative Assessment conferences/workshops, and SAE US Government Industry Meeting.