Think global, buy local? The idea of limiting one’s personal consumption to national, regional or local boundaries is an excellent way to reduce personal carbon footprints and help establish small, human-scale economies. The shorter the supply chain, the less transport energy used, and the less noise and carbon emitted. A better quality of life for all, that’s the idea. Vegetables from a food-coop, for instance, or from a farmer’s market. Or growing them yourself. You already do that? Great. But, no offense, I’m pretty sure this doesn’t help you to resist the delicious smell of a freshly brewed espresso. Does it? Well, you still pour olive oil over your salad from time to time; be honest! No? Still, I’m absolutely convinced that you can’t stop yourself from sipping the healthy fair trade green tea that makes the bikram yoga session complete. Right? Gotcha! Apparently, when you live in the northern hemisphere or Oceania, “buying local” quickly faces limits. There is always stuff that’s just too good not to import.

Despite the fact that most people nowadays cover long distances by flying, a majority of trade goods are still being shipped in the true sense of the word. Per item, the cargo ships that transport our cocoa from Ecuador to Belgium and the Balsamic vinegar for our salad from Italy to the US, are surprisingly efficient. However, they all run on heavy oil, also known as bunker fuel – the cheapest and dirtiest of all fuels. However, despite the overwhelming percentage of heavy oil-run freighters, ships are not naturally designed to burn dirty fossil fuels. They can harvest other energies, too – most abundantly, of course, the wind. In order to do so, there are more technologies around than sails, and there is more to use than wind. Read today about what alternative ideas for shipping have come up so far, how much progress has been made in their development, and whether we’re likely to see any low-carbon transport alternatives on our oceans in the near future.

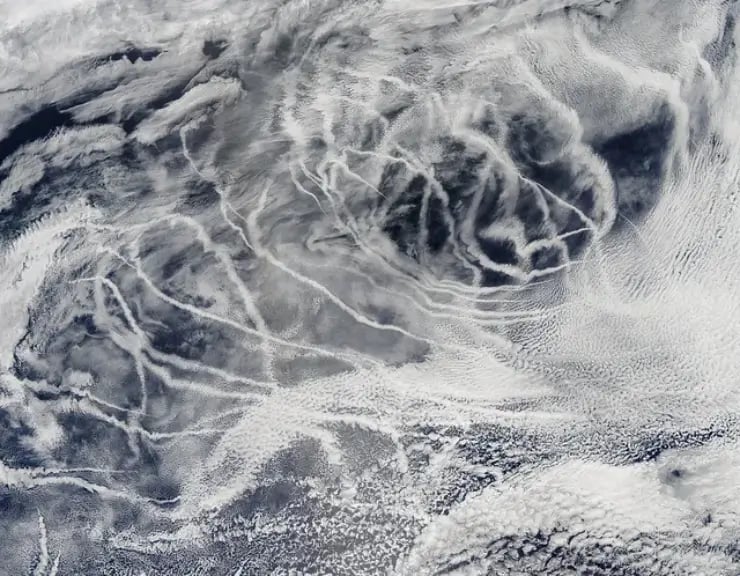

First of all, let’s look behind the current state of affairs in shipping. Heavy oil engines emit not only carbon dioxide and thick black clouds of particulate matter, but also sulfur dioxide. The very moment the ship’s exhaust fumes mix with clouds, precipitation turns into acid rain. As you can see in the article image, a ship’s exhaust is so mighty it can also form clouds. That’s why coastal areas with heavy traffic, such as the U.S. coast, the English Channel, or the Baltic sea, for instance, already fall under the ECA, or emission controlled areas. These areas have tougher marine emission standards than the open sea. Ships that operate in them need to have a second fuel on board, a slightly cleaner one, with a currently permitted maximum sulfur content of 1%, which drops to 0.1% in 2015. Not only ECAs, but the open seas will also see stricter regulations. The general limit will drop from 3.5% to 0.5% by 2020, according to IMO regulations that will be reviewed in 2018. With emission standards becoming stricter, the fuel used gets better, but also more expensive until, finally, even the conservative shipping industry is forced to think about energy efficiencies that go beyond the bare slowing down of vessels.

The most efficient, and the most tried-and-tested, way of getting goods from A to B is to sail. No fossil energy is required to drive a ship while under pure sail. This embodies the sustainability principle of consistency – blending in with a natural cycle, going with the wind. While remaining popular for leisure craft, the classic sailing principle has almost disappeared from cargo shipping. Almost. As of 2013, there are still two classic-style sailing ships operating commercially, or at least two that I know of. The first is Undine, a 37-meter long, 80-year-old steel gaff schooner that ships 70 tons of cargo and eight passengers from the German city of Hamburg to the North Sea island of Sylt twice a week. The island can only be reached by sea or by a rail causeway. That’s why, in this case, prices for sailing the cargo can compete with conventional road and rail transport. In a documentary by German broadcaster NDR, the ship’s captain mentions a big media and industry interest in his cargo sailing revival. According to him, the competitive edge of almost carbon-neutral transport has made the order book of his company, Windjammer Shipping, explode. The second commercial sailing ship still operating is the Tres Hombres, a 32-meter brigantine clipper with a freight capacity of 20-30 pallets and a gross registered tonnage of 50. It is run by the dutch company fair transport on regular transatlantic passages, carrying rum, wine, and other general freight. Fair trade, of course.

The main drawback of these historic sailing ships is the labor-intensive, complicated rigging of the sails, and their weak motors making schedules vulnerable to calm weather conditions. The rigging also impedes quick access to the holds, requiring longer loading and unloading times. Still, the two sailing ships have found their niches in shipping organic and fair trade products. On a larger scale, however, unpredictable shipping times are not exactly in line with globalized just-in-time production… Moreover, maintenance of these old-timers is costly, and capacity very limited. But they work, and they work well. As they did for centuries in pre-Suez and pre-Panama times. And still – the history of sailing ships for large quantities of cargo might be revived soon with a large, newly-designed, 21st-century-atuned sailing vessel. Both the fair transport and the Windjammer Shipping companies support development of the Ecoliner, a 130-meter, 8000-ton hybrid sailing cargo vessel.

The Ecoliner’s four masts will boast dynarig sails, a 1960s invention that has proved its 21st century chops over the 100,000 nautical miles that the luxurious 88 meter Maltese Falcon (the one in the picture) has sailed so far. The main advantage of the dynarig system is fully automated operation. Electronically operated rotating masts align with the wind and make way for cranes when loading. Dykstra, the naval architect that designed Maltese Falcon and Ecoliner, have already built big sailing ships like the Rainbow Warrior III for Greenpeace that serve as examples of the beneficial effects of simultaneous sailing and motoring. Equipped with the same sail technology as the Ecoliner, but having different dimensions, is a 330 ft Valemax bulk carrier for coastal sailing. This ship will be run on a hybrid system of wind (three masts with dynarig sails) and biomethane powered engine. The B9 Energy Group (UK) stands behind the technology for this project and a 12-year simulation in average North Sea weather conditions found a potential to lower fuel consumption 46-55% due to the sails. To put the higher upfront investment needed for the alternative concept into perspective, B9 offers future ship buyers a special deal to better calculate their lower operational costs in advance: buying the ship is bundled with a fixed contract for the biomethane price. How can B9 predict the market price for methane, you might ask? Well, they can’t. But they don’t speculate, either. Their secret is in-house production – B9 also runs a municipal waste plant that captures biomethane. Find pictures and more information on the B9 Valemax in an excellent businessweek.com article here.

As I mentioned in the initial paragraphs, the ways to capture wind power go beyond plain sails. Various types of wind-fossil hybrid systems are to hit the market in the coming years. So far, only two of them have reached the production stage. They do provide ships with additional thrust by harnessing the wind, but they both look pretty different from what you would expect on a sailing ship. The first and most established is a kite made by the Hamburg-based SkySails company. It is mounted to the very front of a ship, starts and lands automatically, and when operating, flies infinite rounds of “eights” in front of the vessel at heights of several hundred meters, dragging the huge vessels like a kites on a kitesurfer. They are just much, much bigger and the stunts are non-existent. See pictures here. The kite can be mounted to any ship that has enough space to mount its mast and it supplements any existing propulsion system. The main advantage compared to deck-level sails are the stronger winds at the greater heights where the kite flies. So far, however, the only kite in operation is small. According to a Wikipedia article, the 160-square-metre (1,700 sq ft) kite that was installed on the MS Beluga Skysails container ship in 2007 saves 10-15% fuel when operating, which leads to 5.5% average annual savings. With plans for 1,600-square-meter kites (17,000 sq ft), we can expect up to 50% energy savings, once the global economic crisis calms down and shipbuilders start investing again. Cost-wise, the company claims 50% savings when comparing one kwH of propulsion generated by the kite to one generated conventionally.

Here’s a video with flying kites on different ships. To see how they are started, check out this video from 0:50 on.

The second wind-fossil hybrid system already operating on a cargo ship is also made in Germany. Rotor ships, or Flettner ships, after its inventor, have giant vertical cylinders mounted on deck that look like oversized chimneys. These “rotors” harness wind power by, would you have imagined?, rotating. Wind turbine manufacturer Enercon employs this system in its 130m-long, RoLo, E-Ship 1. This ship is equipped with four rotors, each one 4 meters thick and 27-meters high. It is used in the marine transport of wind turbine components, but figures for the savings that the Flettner cyclinders provide have not, unfortunately, been published. Here’s a video with German comment showing the ship in operation and explaining the Magnus effect, the core of the Flettner principle:

An experimental vessel that entirely runs on photovoltaic solar power completed a circumnavigation last year. It can hardly be called a cargo ship, and has a relatively poor average speed of 5 knots, but with a 90-ton dead weight and 8.5 tons of batteries, the MS Tûranor PlanetSolar could pave the way for more practical hybrid solar systems. It certainly proved that solar panels can withstand rough conditions at sea, especially making the point that the omnipresent threat of saltwater corrosion can indeed coexist with semiconductor electronics.

Wind-solar hybrid systems that support conventional propulsion have been explored by many, in theory. One of the best known ones is the Japanese solar boat manufacturer eco marine power. Through its Aquarius Eco Ship study, the company invented a system of large, rigid photovoltaic panels that serve as sails at sea. Even when moored or tied up, the adjustable solar panels provide additional power, saving energy and emissions during the daytime, and, with power management, also at night. It can be adapted to all sorts of cargo and passenger ships, but the actual savings have not been estimated precisely.

A very different, very conventional approach to save energy when shipping cargo was taken by Danish shipping company Maersk. Its most recent redefinition of the “largest cargo vessel in the world” came through the launch of the Mærsk McKinney Møller. This 400-meter-long, 59-meter-wide giant that hosts 18.000 containers was called environmentally friendly in many media articles, although neither wind, nor sun are used on board in any way. It is the sheer, gigantic upscaling, along with a few other measures, that makes the ship more efficient than others. Maersk claims a 50% lower carbon footprint with this new vessel when compared to the industry average for a container on Europe-Malaysia passages.

Waste heat recovery from the exhaust, two propellers that run at lower revolutions, plus a 2 knot lower top speed (now 23 knots) are the ship’s efficiency secret. On the life cycle front, its self-entitled “Cradle-to-Cradle Passport” lists all of the ship’s building materials and components in detail to enable better maintenance and disassembly at the end of its lifespan, thus paving the way for better recycling. For its entire fleet, the company has achieved a 25% carbon emission reduction in the past 5 years. From 2007 to 2020, a 40% reduction is targeted.

Apparently, there is already enormous room for improvement by taking small, conventional measures, as the Maersk example shows. When you take this potential and spice it up with all the renewable energy innovations listed here for shipping, it is clear which direction cargo shipping has to take. All we need now is a critical mass of pioneering shipping companies committed to taking the right steps. Can it be all that hard to put a freaking kite or sail on your new generation vessel? I mean, what we’re talking about isn’t nothing, it’s about the rise or fall of incredibly gorgeous chocolate, a world traveling pleasure with ingredients that unfortunately grow far out there in the tropical jungle…

Article image shows ship tracks shot by NASA Goddard (image CC BY 2.0).