According to a report by the European Environment Agency, transport was responsible for around a quarter of the EU's total CO₂ emissions in 2022. Road transport accounted for 71.7 per cent of this. Even if the largest share is caused by the use of vehicles, it is also worthwhile for car manufacturers to take a look at the manufacturing process. OEMs of the time have recognized this and are driving carbon reduction into their supply chain. But how exactly can the carbon footprint of car manufacturing be reduced?

Perspectives in Carbon Footprinting: OEM vs. Suppliers

When it comes to conducting a carbon footprint in the automotive industry, the perspectives, scopes and system boundaries vary significantly between OEMs and suppliers. This discrepancy stems from the different roles and responsibilities each entity holds within the supply chain, as well as their objectives and priorities in sustainability efforts.

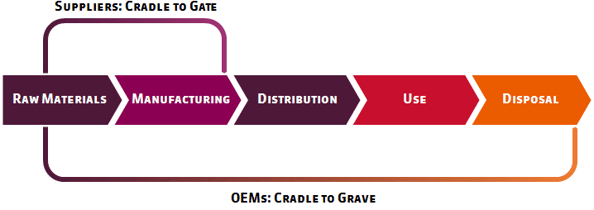

Supplier Perspective: Cradle to Gate Approach

Tier 1 and Tier 2 suppliers typically adopt a cradle-to-gate approach, which assesses the environmental impacts of their manufacturing processes, including sourcing of raw materials up to the point of product delivery to the OEM. Suppliers are often driven by OEM requirements and contracts, which may specify the need for carbon footprint assessments up to the gate.

OEM Perspective: Cradle to Grave Approach

OEMs typically should adopt a cradle-to-grave approach when assessing the CO2 footprint of their vehicles. This approach considers the entire life cycle of the product, from raw material extraction and manufacturing to use and end-of-life phases. However, they often face challenges in considering the use phase and end-of-life aspects due to limited data availability and comparability issues.

Collaboration Opportunities

While OEMs and suppliers operate with different scopes, there is an opportunity for alignment and collaboration, to ensure transparency and consistency across the supply chain. By understanding each other's perspectives and priorities, automakers and suppliers can identify opportunities for CO2 emissions reduction and resource efficiency throughout the supply chain.

Establishing industry standards and best practices for carbon footprinting can facilitate consistent methodologies and data sharing among OEMs and suppliers. This fosters transparency, trust, and collective action towards achieving sustainability goals across the automotive sector.

Comparing Battery Electric Vehicles (BEV) and Internal Combustion Engine Vehicles (ICEV)

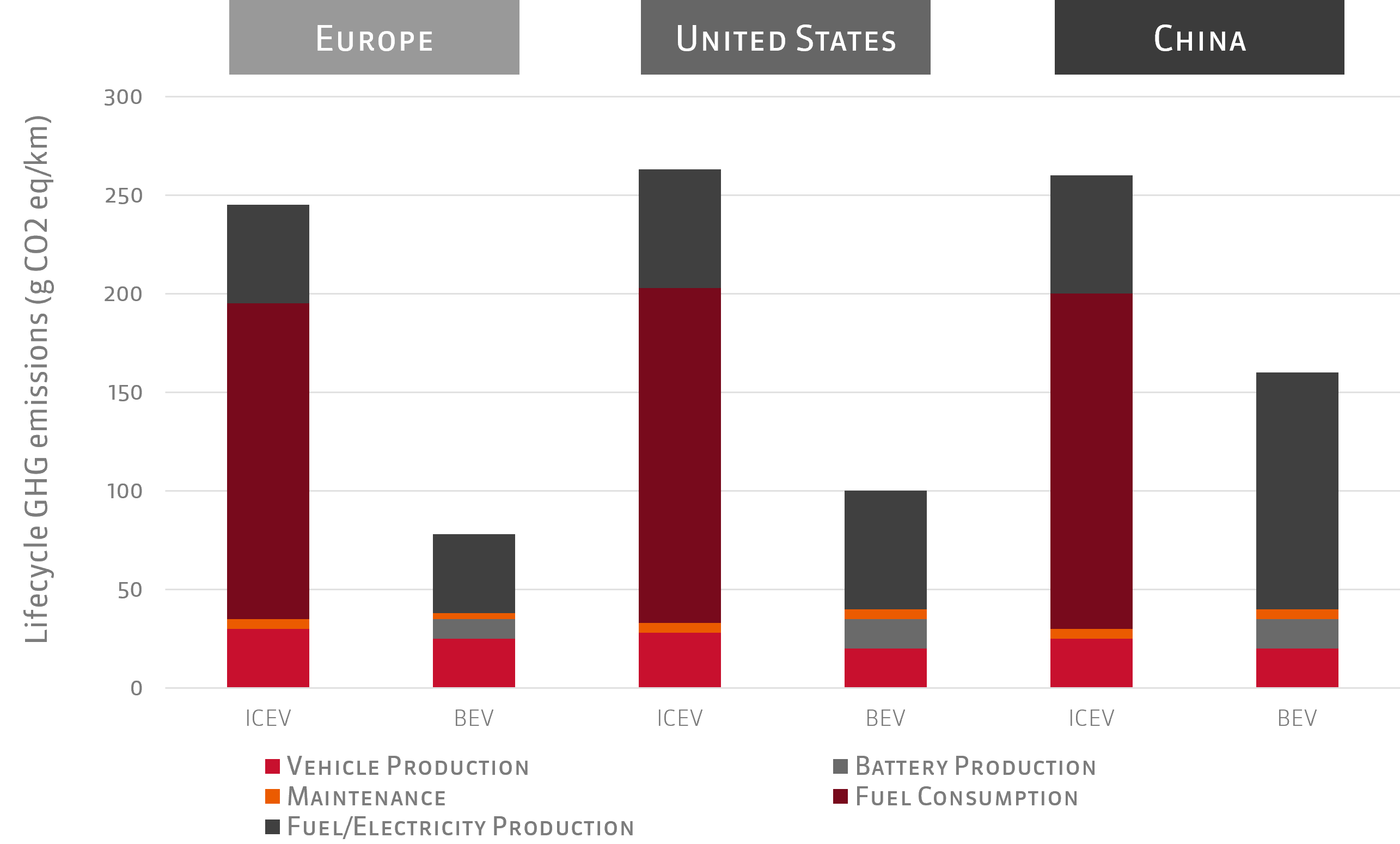

Comparing the environmental impact of Battery Electric Vehicles (BEVs) and Internal Combustion Engine vehicles (ICEVs) poses challenges due to differences in materials, production processes, and usage patterns. However, studies indicate that BEVs offer significant environmental benefits over ICEVs, particularly in terms of GHG reduction.

While the raw material and production phases of BEVs have higher carbon footprints, the use phase significantly reduces emissions, especially with renewable energy sources. Over the vehicle's lifetime, the lower emissions from BEVs offset the initial carbon footprint associated with battery production, leading to a lower carbon footprint of electric cars overall. Studies show that for mid-sized vehicles the break-even point occurs at a mileage of 60 – 80,000 km, i.e. within a car’s typical lifespan.

Source: https://www.cotes.com/blog/greenhouse-gas-emissions-from-ev-vs-ice-vehicles

Source: https://www.cotes.com/blog/greenhouse-gas-emissions-from-ev-vs-ice-vehicles

Ensuring proper end-of-life handling of batteries is crucial to maximize the environmental benefits of BEVs. Recycling and repurposing battery materials can minimize waste and reduce the environmental footprint of disposal. Implementing effective battery recycling programs and developing secondary use applications for retired batteries can extend their lifespan and contribute to a more sustainable battery supply chain.

Carbon Emission Hotspots in Automotive Manufacturing

When considering the climate impact of a car, it's natural for most people to focus on factors related to vehicle usage, such as fuel consumption and tailpipe emissions. Indeed, studies often highlight the significant contribution of vehicle operation to overall carbon emissions. However, to truly understand the environmental impact of cars, the entire life cycle of a vehicle, including raw materials and manufacturing, must be considered.

Climate Impact of Steel

Steel is a fundamental material in automotive manufacturing, renowned for its strength, durability, and versatility. However, its production and usage contribute significantly to carbon emissions throughout the vehicle lifecycle.

The production of steel involves energy-intensive processes, particularly in the raw material phase. The smelting or melting of iron ore to produce steel requires substantial amounts of energy, primarily sourced from fossil fuels. In addition, the manufacturing processes of pressing, stamping and moulding steel components also require a considerable amount of energy. Moreover, the high density and weight of steel increase transport emissions during the transport and assembly phases.

Various approaches are available to mitigate the climate impact of steel: the increased use of recycled steel to minimise energy-intensive raw material production, the use of renewable energy sources such as solar and wind energy for steel production and the transition to hydrogen-based steel production methods.

Climate Impact of Aluminum

Aluminum is widely utilized in the automotive industry due to its lightweight properties, which contribute to improved fuel efficiency and reduced emissions during vehicle operation. However, the production of aluminum is energy-intensive, posing challenges in terms of greenhouse gas emissions (GHG).

Emphasizing aluminum recycling and closed-loop systems is a key strategy to reduce the carbon footprint of aluminum. Recycling aluminum requires significantly less energy compared to primary production, resulting in lower emissions.

The introduction of advanced technologies, such as prebake and inert anode smelting processes, can improve energy efficiency and reduce the global warming potential of aluminum production. In addition, the integration of renewable energy sources such as hydropower or solar energy into the smelting process further mitigates the environmental impact.

Climate Impact of Plastics

Despite metals, plastics plays also a vital role in car manufacturing, offering versatility, durability, and design flexibility. However, the production and usage of plastics contribute to GHG emissions, primarily driven by energy-intensive processes such as polymer production and injection molding.

To mitigate the environmental impact of plastics in the automotive sector, automakers can focus on bioplastics, renewable materials, energy efficiency, and recycling within a circular economy model.

Optimizing Carbon Footprint in Car Manufacturing

Reducing the carbon footprint in car manufacturing involves implementing various optimization strategies aimed at minimizing emissions and enhancing energy efficiency throughout the production process:

- Incorporating more sustainable materials such as eco-friendly composites, bio-based plastics, recycled steel and aluminum into car manufacturing

- Establishing closed-loop systems within the manufacturing process to facilitate the recycling of materials like steel, aluminum, and plastics. This approach minimizes waste generation and reduces the need for virgin raw materials

- Streamlining intra-company transport systems and implementing efficient logistics planning, layout optimization, and automation technologies

- Leveraging combined heat and power (CHP) generation systems and utilizing waste heat generated from power generation processes

- Implementing advanced painting techniques such as powder coating, water-based paints, and UV-curing processes

- Implementing energy-efficient equipment, upgrading production technologies, and adopting lean manufacturing principles

- Exploring carbon capture and storage (CCS) technologies to capture CO2 emissions generated during the manufacturing process and prevent them from entering the atmosphere.

Automotive Sustainability Trend Study

Find out more about carbon reduction measures and targets in the automotive industry compared to other sectors.

Comprehensive Life Cycle Assessment (LCA) in Car Manufacturing

While GHG emissions and the Product Carbon Footprint are significant aspects of the total environmental impacts, a comprehensive Life Cycle Assessment (LCA) of car manufacturing must consider a broader range of factors. Other hazardous effects such as air pollution, resource depletion, land use, and water consumption play crucial roles in assessing the environmental performance of the manufacturing processes of cars.

By considering these other effects, car manufacturers can make more informed decisions about reducing their environmental footprint and conserving natural resources, contributing to holistic environmental stewardship.

Sustainable Car Design & Engineering in the Automotive Industry

In addition to creating more climate-friendly production processes, sustainable design and engineering can help to reduce greenhouse gas emissions:

Here, the use of recycled and recyclable materials is key. In addition, advances in aerodynamics and lightweight construction techniques are contributing to improved fuel efficiency and lower emissions during vehicle operation. But also the integration of electric and hybrid propulsion systems further reduces reliance on fossil fuels, leading to lower carbon emissions over the vehicle's lifecycle.

Obtaining Proper Data for Carbon Assessments: From GWP to IMDS

%20(1500%20%C3%97%201500%20px)%20(1)-1.gif?width=437&height=437&name=Kein%20Titel%20(Video)%20(1500%20%C3%97%201500%20px)%20(1)-1.gif)

When conducting PCFs in car manufacturing, it is crucial to collect primary data at hotspots to ensure informed decision making. As a result, OEMs are increasingly requiring their suppliers to provide precise data on the global warming potential (GWP) of materials and components delivered.

This is where the International Material Data System (IMDS) and appropriate software solutions come into play. IMDS is a centralized database used by the automotive industry to manage and exchange material data for compliance and reporting purposes. Its robust data management capabilities make it a trusted source for obtaining comprehensive data for environmental assessments.

Recognizing the significance of sustainability in the automotive industry, IMDS 15 now supports the exchange of standardized Product Carbon Footprint (PCF) information in alignment with the Catena-X PCF Rulebook. This update enables OEMs and suppliers to provide and access verified GWP data directly within IMDS, making PCF reporting an integrated part of the material data workflow.

Discover IPOINT Product Sustainability for Automotive

Get standardized, Catena-X aligned PCF capabilities across your supply chain – including automated data mapping, IMDS integration, and scalable lifecycle analytics.

IPOINT Product Sustainability offer advanced capabilities for integrating environmental data throughout the product lifecycle: streamlining the environmental assessment process while ensuring data accuracy and consistency at the same time.

- Using our Smart Connector you can seamless retrieve PCF information directly from the IMDS database

- Through Smart Mapping and the included machine learning algorithms you can automatically map bills of material (BOM) with PCF and LCA datasets

Contact our sustainability experts for the automotive industry to gain more insight into how your greenhouse gas emissions can be reduced in the long term.

Frequently Asked Questions

What is the carbon footprint of car manufacturing and why does it matter?

The carbon footprint of car manufacturing refers to all CO₂ and GHG emissions generated during a vehicle’s life cycle—from raw material extraction (steel, aluminum, plastics) and component production to assembly, transport, and upstream energy consumption.

It matters because manufacturing can account for 20–30% of a car’s total lifecycle emissions, making it one of the largest climate impact hotspots in the automotive industry. Reducing these emissions helps manufacturers meet climate targets, improve efficiency, and comply with emerging sustainability policies and reporting standards in Europe and worldwide.

What are the main emission hotspots in automotive manufacturing?

Key hotspots include:

- Steel production (energy-intensive, major CO₂ source)

- Aluminum production (high electricity consumption)

- Battery cells (for EVs, significant CO₂ and energy demand)

- Plastics and composites (petroleum-based materials and molding processes)

- Paint shops and surface treatment (high heat and fuel consumption)

Transport, in-plant logistics, and auxiliary systems (heating, cooling, compressed air) also contribute to a vehicle’s GHG footprint. Understanding these hotspots helps manufacturers target reduction measures and optimize processes.

How can OEMs and suppliers reduce the carbon footprint of vehicle production?

Carbon reduction strategies include:

- using recycled steel, aluminum, and plastics

- switching to renewable energy for production lines

- implementing closed-loop material systems

- improving energy efficiency in stamping, molding, and painting

- optimizing logistics and internal transport routes

- applying lean manufacturing and smart automation

- utilizing carbon capture technologies in high-emission processes

Consistent lifecycle data and standardized PCF calculation methods help OEMs and suppliers identify realistic reduction opportunities.

What data is needed to calculate a reliable Product Carbon Footprint (PCF) in the automotive industry?

A reliable automotive PCF requires primary data from material suppliers, manufacturing energy consumption, upstream fuel and electricity factors, and accurate Bill of Materials (BOM) structures.

Today, OEMs increasingly ask suppliers to provide Global Warming Potential (GWP) data via IMDS 15, following the Catena-X PCF Rulebook. Access to verified datasets, LCA databases, and automated data mapping tools ensures consistent calculations across the supply chain.

How does IMDS 15 change PCF reporting for suppliers?

IMDS 15 introduces the ability to exchange Product Carbon Footprint (PCF) data directly within the International Material Data System. For suppliers, this means that PCF reporting becomes a standardized and integrated part of the existing material data workflow. Instead of sending CO₂ or GWP information through separate spreadsheets or custom formats, suppliers can now provide Catena-X aligned PCF values directly to OEMs through IMDS.

This improves data quality, comparability, and transparency — and helps suppliers meet growing OEM expectations without creating new reporting systems.

How can automotive companies streamline PCF calculations and comply with IMDS 15 and Catena-X requirements?

Automotive OEMs and suppliers can streamline Product Carbon Footprint (PCF) calculations by using standardized models and workflows that support consistent, Catena-X aligned data. With IMDS 15 now enabling the exchange of PCF information based on the Catena-X PCF Rulebook, companies need tools that help them produce traceable and comparable climate data across different product types, materials, and lifecycle stages.

Suppliers can simplify PCF generation by using iPoint Product Sustainability:

- IPOINT Product Sustainability Core provides a ready-to-use, parameterizable PCF model for fast and reliable PCF calculations without internal LCA expertise.

- IPOINT Product Sustainability Growth adds customizable PCF models and supports more complex product setups, product variants, or detailed data requirements.

OEMs and larger manufacturers can use IPOINT Product Sustainability Scale, which offers fully scalable lifecycle analytics, enabling automated and portfolio-wide PCF and LCA creation across many vehicle models and components.

Together, these packages help automotive organizations deliver standardized, regulation-ready PCF data that integrates into IMDS 15 processes and supports compliance with Catena-X methodologies — without requiring internal sustainability teams, complex IT landscapes, or external consultants.

.png)