Electric cars and e-mobility are hotly debated issue right now, both in scientific circles and in the media. Some herald it as enabling mobility with fewer carbon emissions, while others claim battery production makes electric vehicles (EVs) just as ‘dirty’ as cars with internal combustion engines (ICE). These opposing positions can lead to a high level of uncertainty, both for consumers and for policy makers. As is so often the case, the verdict is a stout “it depends”, so it’s worth taking a closer look at the life cycle of electric cars.

Assessing the Carbon Footprint of Electric Cars

At our Life Cycle Workshop 2019, Dr. Kirsten Biemann from the ifeu Institut für Energie und Umweltforschung (Institute for Energy and Environmental Research) in Heidelberg presented a meta-study on the climate impact of electric vehicles. The focus was on the large number of influencing factors and the resulting discrepancy in the outcomes. For example, ifeu determined results between 50 and 210 g CO2 per kilometer driven. The enormous discrepancy is due to a variety of factors, primarily the lifetime mileage of a vehicle, the type of driving (short or long distance), the energy mix used to charge the vehicle during the use phase and the effects of battery production.

Factors Influencing the Carbon Footprint of EVs

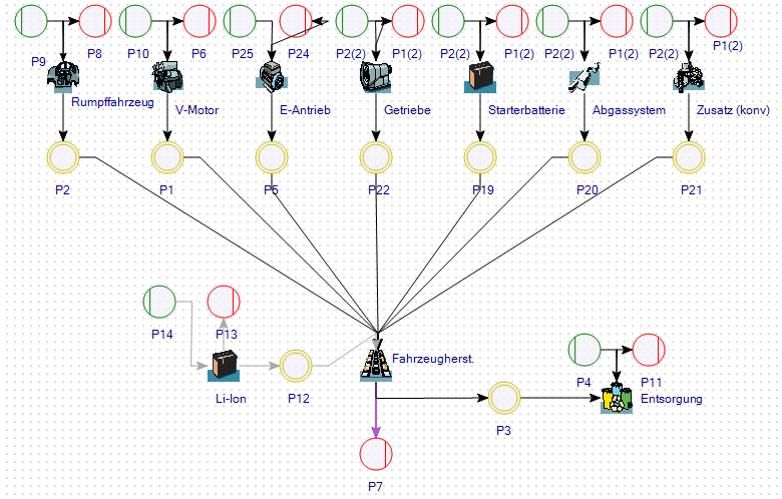

ifeu then created its own model, based on a generic, mid-sized electric car. The study focused on the vehicle’s overall carbon footprint and the resulting climate impact over its entire life cycle. Modeling was done with our LCA software Umberto developed, using the ecoinvent database. The following results are all based on the Umberto model seen below:

Excerpt of a carbon footprint model for a generic e-car created with the software Umberto

Calculating the energy mix correctly is key so, assuming an average use phase of 10-12 years, the model also took projected future changes into account. Currently, the energy mix in Germany still includes a high percentage of fossil fuels; but during the time the car will be on the road, it is expected to move toward much more renewable energy, and thus a considerably smaller carbon footprint.

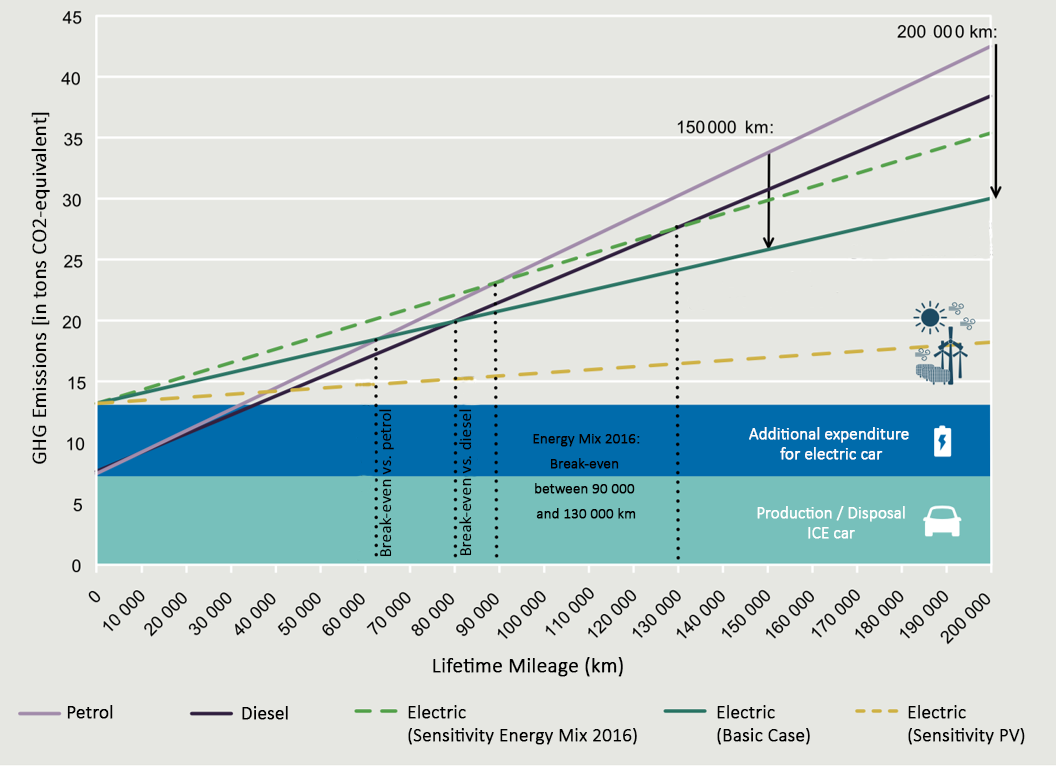

Another important factor is the vehicle’s overall lifetime mileage, which can vary greatly. So rather than simply arriving at a fixed number for CO2/kwh used, ifeu decided to pinpoint break-even points as identified by their comparative carbon footprint analysis.

Carbon footprint of e-cars compared to ICE powered cars under consideration of the energy mix (Source: Agora Verkehrswende (2019): Klimabilanz von Elektroautos.)

Generally, the initial energy input during the manufacturing phase is about the same for both electric and conventionally powered cars. But EVs add another large energy chunk to their ecological impact in the form of battery production. So, it’s only during the use phase that e-vehicles really shine: their CO2 impact is a lot smaller than that of ICE powered cars and the relative CO2 savings increase the longer the car is on the road.

Which brings us back to the break-even point. In this mid-sized car scenario, it occurs between 60 – 80,000 km, well within a car’s typical lifespan.

Fine-Tuning Results by Changing Modeling Parameters

By adjusting some of the variables in their model, ifeu was able to show just where the critical points are to make e-mobility more sustainable. In a scenario called “City”, the analysis was based on the fact that electric cars are often the second vehicle in a household and therefore mainly used in city traffic for short range driving. Based on that, the model assumes a smaller, low-range battery and also lower lifetime mileage.

The result is a break-even point that is reached much sooner, at around 40,000 km. So, despite the higher up-front carbon input during the production phase, the biggest reduction of climate impact with electric vehicles remains during their use phase. Which makes the energy mix used to power them a key issue!

The Dirty Little Secret of Battery Production

The critically important factor in the life cycle of an EV is still its battery. Nearly 50% of the battery’s overall CO2 impact is generated during its manufacturing phase, due to the high energy input required. So, the energy mix used is a crucial variable.

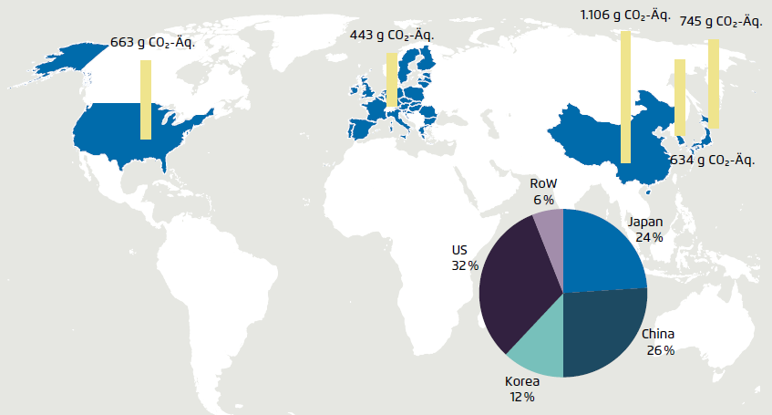

Currently, EV batteries are mainly produced in the US, China, Japan, and Korea – all of which still have high rates of fossil fuels in their energy mix. A switch to using more renewable energy during battery production could thus significantly lower the overall carbon footprint of the vehicle.

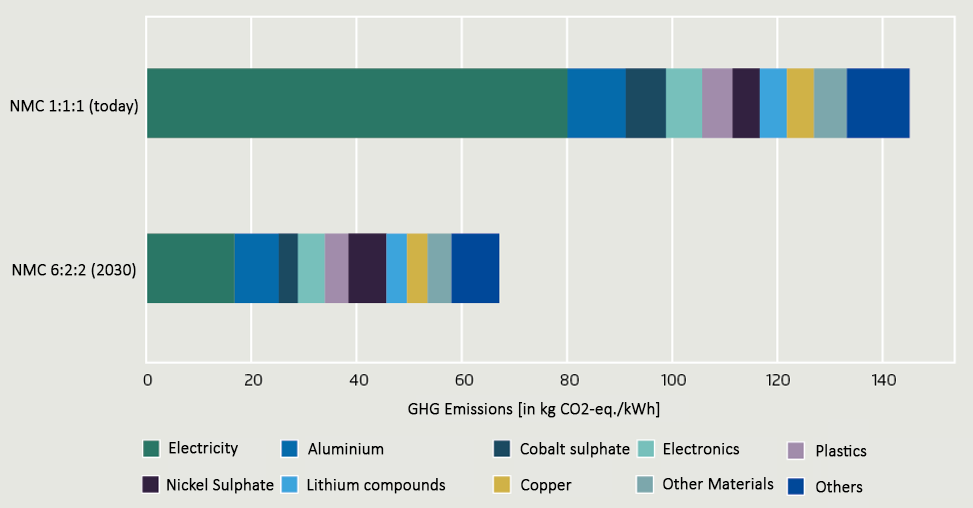

Power consumption and energy mix in cell production dominate the CO2 balance of the battery (Source: Agora Verkehrswende (2019): Klimabilanz von Elektroautos.)

You can read more about the role of batteries in e-mobility in our blog article on LCA of lithium-ion batteries.

Assuming that cell production continues its dynamic advancement – using fewer raw materials and less energy while achieving higher efficiency – the break-even point of a 35 kWh battery could be reached as early as 30,000 km, or 50,000 km for a longer range, 60 kWh battery.

Future Outlook: More Sustainable Electric Cars by 2030

So, how can we improve the LCA numbers for e-vehicles by 2030 and achieve a lower carbon footprint?

- Decarbonize the energy mix both in manufacturing and use

- Increase engine efficiency

- Lower charging losses

- Improve the efficiency of battery production

These suggested improvements could cut the carbon footprint for battery production in half compared with today. In addition, higher lifetime mileage also has a positive impact. In combination, these improvements could make the transition to a truly sustainable e-mobility feasible.

Expected improvement in GHG emissions from battery cell production by 2030 compared to today (Source: Agora Verkehrswende (2019): Klimabilanz von Elektroautos.)

The complete ifeu study is available only in German, but you can find the Executive Summary in English at: https://www.agora-verkehrswende.de/en/publications/lifecycle-analysis-of-electric-vehicles-study-in-german-with-english-executive-summary/

Sustainability in the automotive industry is becoming increasingly important. Overall, the study tells us that when it comes to the carbon footprint of cars and their manufacturing, it is imperative to take a close look and collect accurate data.

iPoint supports car manufacturers and suppliers in collecting the right data, calculating the carbon footprint and identifying hotspots to improve and reduce greenhouse gas emissions. Contact our sustainability consulting and service team, we look forward to working with you on greener mobility.