With the use of electric vehicles on the rise, there’s a lot of buzz about how environmentally friendly they are. While operational impacts are low compared to vehicles powered by internal combustion engines (ICEs), a closer look at all the production inputs, specifically the batteries, reveals a different side.

Possibilities and constraints in Life Cycle Assessments of lithium-ion batteries

This was the talk presented by Andreas Genest, sustainability consultant at iPoint, at the Batterie Forum Deutschland in Berlin in January 2019. The 3-day conference with 350 attendees from politics, science, and economics focused on many aspects of lithium-ion batteries, from manufacturing and sourcing of raw materials, through the newest scientific insights, to the batteries’ increasing use in logistics and e-mobility.

Attention was given mainly to the LCA of batteries in the field of electro-mobility, one of the fastest growing sectors for battery use. Genest presented various LCA studies of lithium-ion batteries and cast light on why their results often conflict.

Lithium-ion batteries and the rise of e-vehicles

The sale of e-vehicles is forecast to increase dramatically and with it the demand for batteries, specifically lithium-ion batteries. So just how much impact does battery production have on the overall Life Cycle Assessment (LCA) of electric vehicles? A commonly held belief is that while e-vehicles are greener to operate than vehicles with ICEs, their overall carbon emissions are simply shifted from the use-phase (less) to the production phase (more). According to LCA consultant Andreas Genest, that statement is mostly true – but also suggests a much more complex question.

“It is important to look closely at what exactly an LCA is focused on”, Genest points out. “With so many different parameters to examine, you can end up with a wide range of results.” When analyzing the life cycle of an e-vehicle, one should look at the entire process, from production of the vehicle, including all upstream chains, through its use phase, and, eventually, to its end-of-life processes.

Are electric vehicles greener?

A commonly asked question is which vehicle type is more environmentally friendly: e-vehicles or those with “traditional” ICEs? When just taking the greenhouse warming potential (GWP) into account – a hot-button issue right now -, gas and diesel powered vehicles have the highest GHG emissions, followed by hybrid electric (HEV), plug-in hybrid electric (PHEV), and finally straight battery driven e-vehicles (BEV), which tend to have the lowest GWP.

But comparing only the GWP of the various vehicle types is not enough. As Genest shows, concentrating on GWP only takes climate impact into account while ignoring other potential environmental impacts, thus limiting the scope of the LCA. When including other environmental parameters a different picture emerges: while BEVs do better relative to GWP, they actually do worse in categories such as ‘ecological scarcity’ or ‘eutrophication’, due to demand for certain materials used in battery production.

A look at the bigger picture reveals that BEVs have a tendency to be more environmentally friendly than ICE-vehicles, but certainly do not have great scores in all impact categories across the board.

This also explains why we see a fairly wide range of results from various LCA studies of lithium-ion batteries: outcomes depend on the assumptions underlying each LCA and which impact categories the analysis chose to emphasize. “That’s why comparison among LCAs is still extremely difficult – each study depends on too many variables” Andreas Genest sums up. Studies even show large discrepancies when estimating the share of battery production in the overall GHG emissions of e-vehicles, ranging from 10% to 35%.

Environmental impacts of lithium-ion batteries – a major factor in LCAs for e-vehicles

It’s worthwhile to take a closer look at what exactly the environmental impacts of batteries are. By far the most critical phases in a battery’s life cycle are production (especially energy use) and recycling, an increasingly important issue.

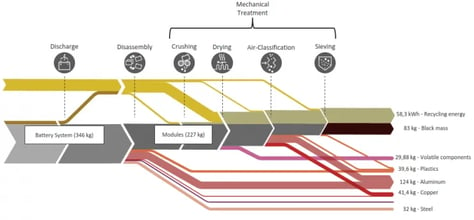

The Sankey diagram below illustrates material and energy flows during the battery recycling process, showing the energy needed for various separation steps as well as the recovered material streams. The first recycling phase alone – disassembly – yields a large quantity of copper, steel, and aluminum, recouping nearly 50% of all materials. Every additional step yields additional material, but also calls for an increasing energy input per unit.

The question is: at which point does the energy input overwhelm the additional gains? Analysis of the recycling process should take a variety of impact categories into consideration, including the “avoided impact” of using recovered versus raw material.

So recycling may not always be the best solution. At some point, depending on your goals, you cross the cost-benefit threshold and the decision may no longer be cut and dry. If taken from a strict climate impact point of view, further recycling may not make any sense, but it may well do so if you’re focused on reclaiming certain rare materials.

In the end, it’s difficult to use LCAs to reach general conclusions: each particular study’s underlying assumptions and choice of impact categories make a difference. However, LCA is a great tool to look at a specific set of parameters and provide specific recommendations for the most favorable options among those parameters. As Andreas Genest sees it, you should always keep the big picture in mind.

Future outlook: more research and launch of Live LCA

After being confronted with the difficulty of comparing the varying results of different LCAs on lithium-ion batteries, the University of Graz and iPoint have teamed up to investigate the matter and conduct their own studies.

Over at TU Braunschweig, the university’s Battery Lab (BLB) is engaged in research and production of new battery types. BLB is to be the first testing ground for ifu Hamburg’s and iPoint’s joint project called “Live LCA”, the next generation of life cycle assessment software, including real-time data monitoring for process modeling and simulation. It’s driven by the specifically developed LCA Software Umberto and has the power to build a life cycle inventory that ties everything together with primary data from, for example, the ecoinvent database, to create a real-time, responsive LCA model.

The project is set to take place in 2019, followed by additional field tests with partners from the Industrial Interest Group, and a tentatively scheduled launch of the new Live LCA software in 2020. For anyone interested in participating, the Industrial Interest Group still welcomes new members.