Product compliance is now a critical factor for companies working with chemical substances in the United States or the European Union. Regulations such as REACH, RoHS, TSCA, and California Proposition 65, as well as broader frameworks like CSRD and CBAM, now determine whether a product can legally enter the market.

This article explains what product compliance means, how it differs from material and environmental compliance, and how global regulations create risks and opportunities. Read on to learn about the biggest practical challenges companies face and how digital tools and iPoint’s solutions can transform compliance from a legal duty into a driver of resilience and growth.

Table of Contents

- Product Compliance: Key Facts at a Glance

- What Is Product Compliance?

- The 3 Core Categories of Product Compliance

- Regulatory Landscape: Key Frameworks Around the World

- Who needs to Comply?

- Practical Challenges in Ensuring Compliance

- Compliance Intelligence: Strategies and Digital Solutions That Work

- How IPOINT’s Solutions Enable End-to-End Compliance

- Conclusion: Future-Proofing Product Compliance

What Is Product Compliance?

Product compliance means ensuring that a product meets all legal, safety, chemical, and environmental requirements before entering a market. It encompasses restrictions on hazardous substances, labeling regulations, testing protocols, and sustainability obligations throughout the supply chain.

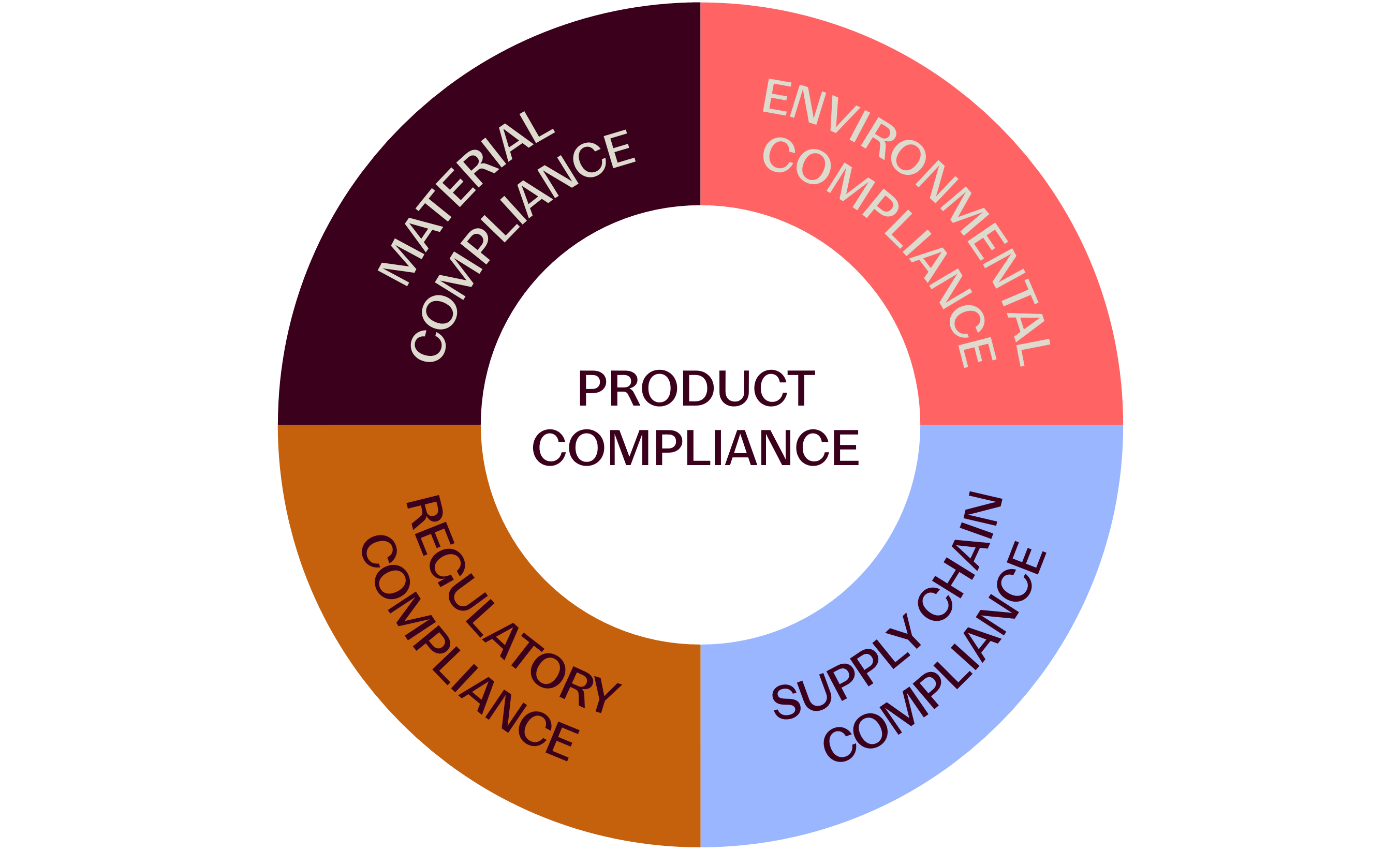

This term is often confused with other forms of compliance, but its scope differs:

- Material compliance focuses on substances in products, such as those restricted under REACH or RoHS.

- Environmental compliance is broader, covering regulations on waste, recycling, and greenhouse gas reporting.

- Regulatory compliance is the umbrella term that spans all legal obligations, with "product compliance" as a key subset.

These overlaps reflect the different nomenclatures used by regulators and industries, ranging from product regulatory compliance to global product compliance. Regardless of the terminology used, the goal remains the same: to ensure that products can be manufactured, sold, and used legally and safely worldwide.

The 3 Core Categories of Product Compliance

To clarify its scope, product compliance can be divided into three core categories:

- Material and chemical reporting: Disclosure of hazardous substances and avoidance of restricted materials

- Product certification: Compliance with technical standards, safety tests, and market-specific requirements

- Producer responsibility: Meeting obligations for recycling, take-back schemes, and extended producer responsibility (EPR)

Take Control of Your Product with

Compliance Intelligence

Streamline your processes and ensure that all of your products meet environmental standards. Automate chemical reporting, monitor hazardous substances, and generate audit-ready documentation all on one platform.

Regulatory Landscape: Key Frameworks Around the World

Global product compliance is shaped by a patchwork of regional and sector-specific rules. Companies must address chemical restrictions, safety laws, and sustainability reporting, often across multiple jurisdictions.

European Union

The EU sets some of the world’s most comprehensive compliance standards, especially for chemicals and manufacturing:

- REACH: Registration and control of chemical substances, including disclosure of hazardous materials

- RoHS: Limits hazardous substances in electrical and electronic equipment

- ELV Directive: Reduces hazardous materials in vehicles and ensures recycling at end of life

United States

In the U.S., compliance frameworks emphasize chemical control and consumer protection:

- TSCA: Empowers the EPA to regulate industrial chemicals and demand risk reporting

- California Proposition 65: Requires warnings for consumer exposure to substances linked to cancer or reproductive harm

Sustainability and Environmental Reporting

Beyond substance rules, companies face growing demands for sustainability disclosures:

- CSRD: Expands EU reporting obligations on environmental and social impacts

- CBAM: Introduces a carbon price on imports, tying compliance to product footprints and supply chains

Who Needs to Comply?

Compliance obligations apply to a broad set of market participants. This includes companies involved in manufacturing, importing, processing, and distribution across regulated markets:

- Manufacturers: Ensure product design and safety compliance

- Importers: Verify that incoming products meet local rules

- Processors: Confirm compliance of inputs and intermediates

- Distributors: Maintain product integrity and pass on compliance information

Failure to comply can result in fines, blocked market access, and damaged trust, so having strong product regulatory compliance systems is essential for global operations.

Practical Challenges in Ensuring Compliance

Even with clear regulations, achieving consistent product compliance remains difficult. Companies face recurring operational and technical barriers that undermine efficiency and audit readiness.

Lack of Supply Chain Transparency

Compliance starts with supplier data, but many companies lack visibility into extended value chains. Without supply chain transparency, it is nearly impossible to confirm that hazardous substances are avoided, or that products meet environmental standards.

Incomplete or Poor-Quality Data

Suppliers often provide inconsistent or outdated information, and smaller partners may lack digital systems. These gaps weaken compliance declarations and put audits at risk.

Different Requirements Across Regions

A product compliant under REACH in Europe may still be restricted under TSCA or California Proposition 65 in the U.S. This patchwork forces companies to track and interpret multiple frameworks, straining compliance teams.

Manual Workflows and Limited Resources

Reliance on spreadsheets, emails, or siloed systems drains resources and increases errors. Disconnected workflows hinder collaboration, delay decisions, and keep compliance managers under constant pressure.

Compliance Intelligence: Strategies and Digital Solutions That Work

Overcoming compliance challenges requires more than ad-hoc fixes. Companies need smart strategies that embed compliance into their core business processes and leverage digital solutions for efficiency and scale.

Embedding Compliance Into Product Development and Sourcing

Compliance is most effective when integrated from the start. By building requirements into product design and sourcing workflows, companies ensure that compliance is not an afterthought but a standard business practice. This reduces redesign costs, accelerates market access, and strengthens product safety.

Centralized Data, Automated Rule Checks, and Scalable Reporting

Digitalization transforms product compliance management. Centralized data repositories ensure consistency across business units, while automated rule checks flag non-conformities in real time. Scalable reporting tools then streamline disclosure processes, making it easier to keep pace with evolving global product compliance requirements.

Supplier Engagement and Audit Readiness

Suppliers are essential partners in compliance. Structured engagement programs, regular data requests, and clear expectations improve data quality across the supply chain. At the same time, maintaining audit readiness – through traceable records and transparent methodologies – ensures credibility with regulators, customers, and investors.

Download the White Paper “Impact Intelligence: The Steering Logic for Compliance & Sustainability” to learn how companies can transform compliance pressure into strategic advantage — and move from reacting to actively driving sustainable product stewardship.

How IPOINT’s Solutions Enable End-to-End Compliance

IPOINT provides companies with scalable digital tools that support the entire compliance journey. From automated material compliance reporting to integrated environmental disclosures, IPOINT’s product stewardship software helps organizations manage complexity, ensure regulatory compliance, and gain supply chain transparency. By embedding compliance into product lifecycles, IPOINT enables businesses to stay competitive while meeting their legal and environmental obligations.

Streamline Product Compliance with Confidence!

Easily manage complex regulations. Automate reporting, ensure data integrity, and achieve audit-ready compliance across global supply chains

Conclusion: Future-Proofing Product Compliance

The next stage of corporate responsibility involves shifting from reactive compliance to proactive, system-driven approaches. Companies that incorporate compliance into the design and sourcing processes early on become more efficient and build trust.

Digital solutions make this possible. By centralizing data, automating checks, and ensuring audit-ready reporting, businesses can ensure long-term compliance and transform regulatory pressure into a sustainable competitive advantage.

Frequently Asked Questions

Which regulations are the most relevant for companies that work with chemical substances?

How can businesses manage compliance across multiple markets and product lines?

A centralized compliance system is essential. Embedding requirements into product design, engaging suppliers, and using digital tools for automated reporting enables companies to meet regional differences efficiently.

Why is product compliance especially critical for automotive and electronics manufacturers?

Automotive and electronics products contain complex materials, chemicals, and components sourced from global supply chains. Regulations such as REACH, RoHS, ELV, and TSCA impose strict substance restrictions, reporting duties, and end-of-life responsibilities. Non-compliance can lead to product recalls, blocked market access, and liability risks, making systematic product compliance essential in these industries.

How does IPOINT support product compliance?

IPOINT’s Product Compliance Software automates chemical reporting, manages supplier data, and delivers audit-ready documentation. Integrated into development and sourcing workflows, it ensures end-to-end compliance across global supply chains.