When it comes to sustainability, all eyes are on the transport sector and the automotive industry in particular. The accelerating concern for climate change has thrust the concepts of sustainability, Environmental Social Governance (ESG) and Corporate Social Responsibility (CSR) into the forefront of the automotive landscape. As the wheels of progress turn, it becomes evident that measuring and mitigating the carbon footprint towards net-zero is not a choice for OEMs — it's an imperative.

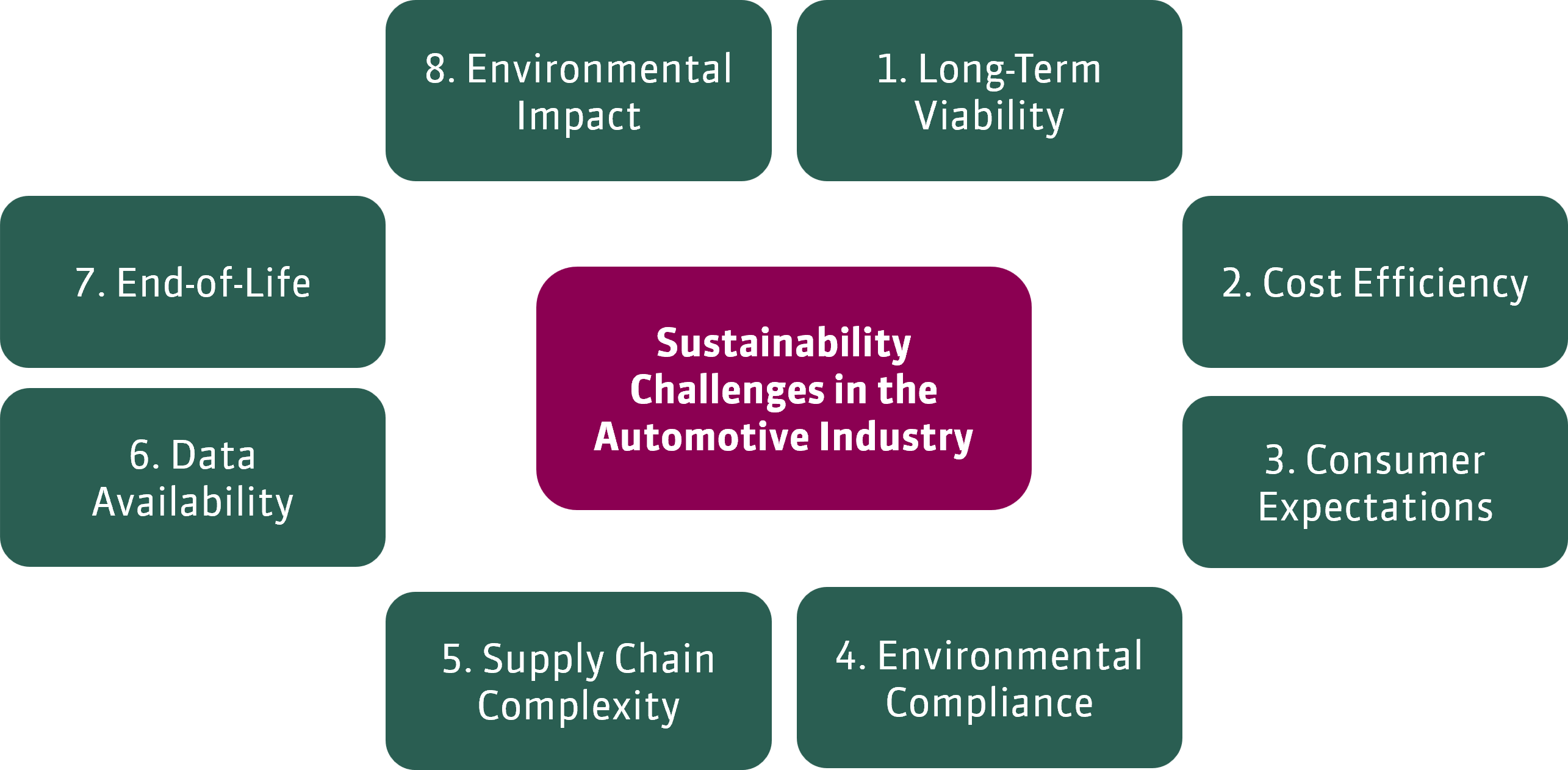

8 Challenges for Car Manufacturing Companies Regarding Sustainability

While the destination is clear — sustainable automotive practices — the path is fraught with challenges that demand innovative solutions car manufacturers have to tackle:

-

Strategic Planning for Long-Term Viability

Sustainability is not a one-time endeavor but a journey that demands continuous commitment. Car manufacturers grapple with the challenge of strategic planning for long-term sustainability while adapting to the evolving landscape of consumer preferences, technological advancements, and regulatory changes. Successfully overcoming these challenges involves a holistic approach that considers economic, environmental, and social factors.

-

Sustainability vs. Cost Efficiency

One of the tightrope walks that car manufacturers have to master is the trade-off between introducing sustainable practices and maintaining cost efficiency.The pursuit of eco-friendly initiatives often comes with an initial price tag. This also applies to the view of customers, who must be able to afford sustainably produced cars. However, sustainability and cost efficiency do not have to contradict each other. On the contrary, both companies and customers can benefit economically from more sustainable products, e.g. through savings in energy and material consumption.

-

Meeting Consumer Expectations

Consumers today are more environmentally conscious than ever, so car manufacturing companies face the challenge of aligning their sustainability goals with consumer expectations. It is important to communicate these efforts effectively to consumers. Building trust and loyalty requires transparency about sustainability initiatives, helping consumers feel confident in their choice of environmentally friendly vehicles.

-

Environmental Compliance and Risk Assessment

In an era of tightening environmental regulations, compliance in the automotive industry has become more critical than ever. Car manufacturers must navigate a constantly evolving landscape of standards, balancing the need for compliance with the drive for innovation to ensure that new, sustainably produced vehicles can be brought to market successfully.

-

Supply Chain Complexity

The complexity of automotive supply chains adds another layer to the sustainability challenge. From raw material extraction to the final assembly, the supply chain is rife with opportunities for improvement. OEMs must navigate intricate webs of suppliers, each with its own environmental impact, to create a more sustainable end-to-end process.

-

Data Availability and Quality

As mentioned above the automotive industry relies on complex supply chains that span multiple tiers of suppliers and involve a wide range of materials and components sourced from around the world. Gathering data on the environmental impact of each component, including factors such as raw material extraction, manufacturing processes, transportation, and end-of-life disposal, can be challenging due to the lack of transparency and standardized reporting across the supply chain.

-

End-of-Life Considerations

The lifespan of a car extends beyond its glory days on the road. The disposal of end-of-life vehicles poses a major challenge. Sustainable practices must encompass the recycling and responsible disposal of components, e.g. interior, ensuring that the environmental impact of a car's entire lifecycle is minimized.

-

Carbon Emissions and Environmental Impact

The most glaring challenge is the industry's carbon footprint. Traditional manufacturing processes, reliant on fossil fuels, contribute significantly to greenhouse gas emissions. Additionally, car manufacturing processes can release pollutants into the air, such as volatile organic compounds from painting and solvent use. Overall, many environmental impacts are associated with the automotive industry - both in production and in use - from water consumption, land use and habitat destruction to air and water pollution.

Automotive Sustainability Trend Study

Learn more about carbon reduction measures and targets in the automotive sector compared to other industries.

8 Sustainability Trends in the Automotive Industry

Various trends have emerged in the automotive industry to address these challenges shaping the landscape of sustainable car manufacturing and driving innovations. Here are some of the prominent trends and innovations defining the current sustainability strategy in the automotive sector:

-

Electric Vehicle Revolution

The rise of electric vehicles (EVs) is revolutionising the automotive sustainability landscape. Major automakers are investing heavily in the development of electric models, driven by the dual goals of reducing dependence on fossil fuels and mitigating greenhouse gas emissions. With advancements in battery technology, EVs are becoming more accessible, offering consumers a greener alternative to traditional internal combustion engines, as the carbon footprint of electric cars is lower overall across all life phases.

-

Hybrid Technologies

Hybrid vehicles, combining traditional internal combustion engines with electric propulsion, have gained prominence as a transitional step towards full electrification. Hybrid technologies offer improved fuel efficiency and reduced emissions, providing consumers with a sustainable option while maintaining the convenience of conventional fuel infrastructure.

-

Circular Economy Practices

By embracing the principles of the circular economy, car manufacturers are focusing on recycling, reusing and reducing waste throughout the production cycle. From using recycled materials in vehicle components to designing vehicles that are easier to disassemble for recycling, the industry is striving to minimize its environmental impact and promote resource efficiency in order to achieve a circular economy in the automotive industry.

-

Carbon Neutral Initiatives

Car manufacturers are committing to making their operations climate-neutral. This includes not only reducing the carbon footprint of car manufacturing, but also those from upstream processes in the supply chain and other downstream life cycle phases, such as distribution, use and end-of-life. The commitment to carbon neutrality and reduce CO2 emissions targeting net-zero aligns with global efforts to combat climate change and positions automotive companies as responsible stewards of the environment.

-

Smart and Sustainable Materials

The push for sustainability extends to the materials used in vehicle manufacturing. Companies are exploring alternative materials, such as bio-based plastics, recycled fabrics, and lightweight composites, to enhance fuel efficiency and decrease the environmental impact of production. The integration of smart materials that contribute to energy efficiency is also gaining traction.

-

Shared Mobility and Connectivity

The shift towards shared mobility models, such as ride-sharing and car-sharing services, is promoting a more efficient use of vehicles. By maximizing the lifespan and usage of individual cars, shared mobility contributes (at least in theory) to reducing the overall number of vehicles on the road and, consequently, their environmental impact. Additionally, connectivity features enable smart transportation systems, further enhancing efficiency and sustainability.

-

Regenerative Braking and Energy Recovery

Innovations in regenerative braking systems allow vehicles to recover and store energy during deceleration. This technology not only improves fuel efficiency in traditional vehicles but also enhances the overall energy efficiency of electric and hybrid vehicles. Regenerative braking is a critical component in the quest for sustainable and energy-efficient transportation solutions.

-

Digital Transformation

The digital transformation of the automotive industry is playing a pivotal role in sustainability efforts. From smart manufacturing processes to data-driven supply chain management, digitization is enhancing operational efficiency and reducing consumption of natural resources. Technologies like Artificial Intelligence (AI) and Internet of Things (IoT) or Digital Twins contribute to predictive maintenance, optimizing energy usage, and minimizing waste.

Initiatives from Automotive Companies around the World

Numerous car manufacturers around the world are demonstrating with their various initiatives how these challenges and trends can be implemented in practice:

Volkswagen's Journey to Sustainability

The VW Group has heavily invested in electric vehicle technology with its ID series. They are aiming to produce EVs at scale to reduce carbon emissions from transportation. Volkswagen has announced plans to make all of its manufacturing plants globally carbon neutral by 2050, focusing on renewable energy sources and energy efficiency improvements. Even if it is not widely known, Volkswagen was one of the first car manufacturers to carry out a life cycle assessment for one of its cars: the Golf III in 1996.

Volvo Cars' Commitment to Net Zero

Volvo has committed to becoming a fully electric car company by 2030, with plans to phase out internal combustion engine vehicles entirely. This development began in 2019, since when all models are available in an electrified version. Another milestone was the year 2023: with the launch of the EX90, EX30 and EM90 and the already existing EX40 and EC40, there are now 5 fully-electric models on the market.

Furthermore Volvo plans to reach 30 per cent average recycled content across its fleet, with new car models having at least 35 per cent recycled content. But that's not the end of the story, as Volvo also plans to become completely climate-neutral - net zero greenhouse gas emissions - and a circular business by 2040. iPoint is proud to accompany and support Volvo Cars on this journey with our expertise and solutions.

Ford's Path to Responsible Manufacturing

The Ford Motor Company is also pursuing sustainability and has set itself high-level goals. In fact, Ford is planning to achieve complete carbon neutrality by 2050, and in Europe already by 2035. With the Mustang Mach-E, F-150 Lightning and the E-Transit, Ford has shown that a wide variety of car types can be electrified.

In addition, the topic of responsible sourcing and human rights is also important to Ford: it has entered into partnerships with the Initiative for Responsible Mining Assurance, the Responsible Supply Chain Initiative, Drive Sustainability and the Responsible Business Alliance to prioritize environmental and social responsibility across its supply chain.

Software Solutions for Sustainability

To master these sustainability initiatives and challenges in the automotive industry, precision, insight, and innovation are essential. The right data collection, coupled with seamlessly integrated software solutions, is necessary for measuring and monitoring carbon footprint reduction targets.

From Product Compliance to Sustainability

The convergence of product and material compliance - both from a social and environmental perspective - with sustainability initiatives is becoming increasingly clear. From responsible sourcing of raw materials, sustainable design and development (eco-design) to manufacturing and end-of-life processes, competences need to be developed for a successful and joint sustainability and product compliance strategy.

For this reason, holistic software solutions are essential. Only when product compliance software is combined with life cycle assessment (LCA) software can the various roles in the company work together to open up the black box of complex products and numerous BOMs.

From Product to Corporate Carbon Footprint

In the automotive industry in particular, it is clear that corporate responsibility with regard to climate protection begins with the product. This means that the corporate carbon footprint (CCF), even if it is characterised by different scopes, and the product carbon footprint (PCF) are increasingly merging. A carbon footprint software that combines both approaches and incorporates the complex supply chains of car manufacturers is therefore indispensable for the path to carbon neutrality.

Automation and Integration of Software Solutions

Time is of the essence as analyzing the carbon footprint or conducting an Life Cycle Assessment ( LCA) of an individual product can be very resource-intensive. Time that is not available given the challenges of today's world.

With iPoint Product Sustainability Automotive, we offer a comprehensive solution that not only automates the analysis of environmental impacts but also integrates it with other business processes, from design and sourcing to product compliance.

Discover iPoint Product Sustainability Automotive

Benefit from a machine learning-based mapping of your production data with environmental data, such as ecoinvent or Carbon Minds, and a connection of material information from IMDS and BOMs.

With iPoint as a partner, the vision of a greener, more eco-conscious automotive landscape comes into sharper focus, demonstrating that sustainability and efficiency can go hand in hand.